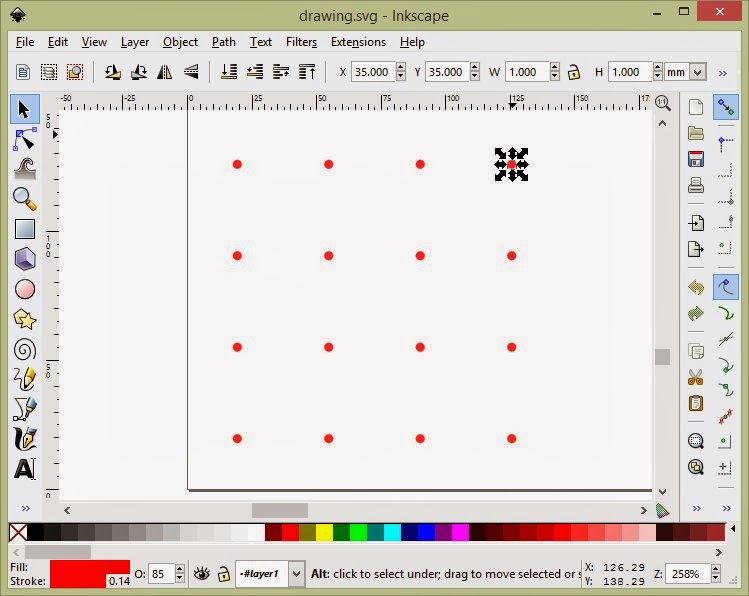

That requires a bit of trial and error as it the material properties need to be taken into account. You can easily make bent sheet metal parts on a laser but you need to design the living hinges yourself. If I need 3D parts, I use the sheet metal tools Solidworks provides. For 2D objects, laser cutting is brilliant, fast and has a very high quality. I use Solidworks for this step, most of the time. I always use the same output.nc file for the files VisiCut exports which makes this very easy to use and a 5 second process to get something to cut. With this in place, I just open a command console, enter SimpleG.bat and the process starts. You obviously need to adjust all paths to your filesystem and the comport to the comport your GRBL communicates through, but you get the idea. Where ever you are at this moment, I recommend creating a batch file and add this command: "G:\Seafile\Software\CNC Software\Laser Cutter\SimpleG\bin\ release\SimpleG.exe " -p COM5 -f "e:\ Users\timob\Documents\output.nc " -F "G:\Seafile\Software\CNC Software\Laser Cutter\SimpleG\ bin\ release\SimpleG-end.gcode " Open a console (hit Win, enter "cmd", hit enter). Install and download everything in the above order. SimpleG for transferring gcode to the laser fast (without interruption of the stream up to a certain speed).Git for Windows (if you use Windows) to clone the SimpleG software.CodeBlocks with MingW to compile SimpleG from sources.VisiCut with some of my own modifications.Laser Cutting Template with multiple layers designed for easy import into VisiCut.I'll go into detail on how I use this down below Chain Paths Extension This is a must have for working with DXF files.Inkscape 0.92 I strongly recommend downloading and installing manually to avoid confusion with the folder structure later.

0 kommentar(er)

0 kommentar(er)